No products in the cart.

3D Printers, Formlabs, SLA

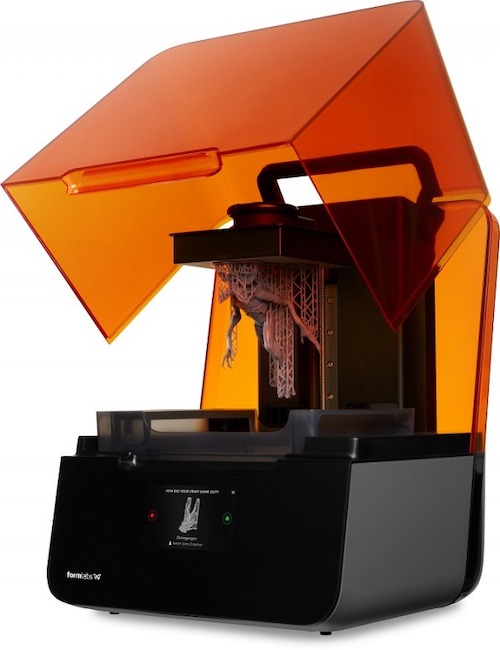

Formlabs Form 3

Availability:

In stock

The world’s first 3D printer working in LFS technology

(Low Force Stereolithography ™)

$ 3,026.43 $ 5,246.80 incl. tax $ 2,460.51 $ 4,265.69 excl. tax

In stock

Formlabs Form 3

Formlabs has developed a new version of the SLA technology to achieve even better results in printing with photopolymer resins. Formlabs Form 3 3D printer uses LFS (Low Force Stereolithography ™) technology, which provides even higher precision of production with increased printing speed. Thanks to the reduced laser spot to 85 micrometers, we can achieve unrivaled accuracy of mapping each detail. Built-in sensors monitor the operation of the device and maintain constant conditions during printing, which guarantees repeatability of production. Get the unparalleled precision of 3D printing in even less time.

SLA technology in a new version

The LFS (Low Force Stereolithography) technology developed by Formlabs allows you to print with much greater precision compared to other SLA 3D printers.

More accurate representation of details

The improved optical system steers a laser beam with a size of 85 micrometers. This ensures exceptional precision and quality of detail reproduction.

Smooth surface of prints

The support structures are even thinner, thanks to which the models have a smooth surface. Easier removal of supports also means shorter processing time of prints.

Extra Features

A complete ecosystem

The Form 3 3D printer is compatible with PreForm software, Formlabs resins, the worktable used in Form 2 and the post-processing equipment: Form Wash and Form Cure.

Convenient file transfer

Upload printable designs via Wi-Fi, USB or Ethernet. Manage your prints conveniently on the 5.5 inch touch screen.

Intuitive PreForm software. Prepare the project and control the printing process.

| Technology | Low Force Stereolithography™ (LFS) |

| Size | 40.5 × 37.5 × 53 cm |

| Working area | 145 × 145 × 185 mm |

| Layer thickness | 25 – 300 microns |

| Compatible resins | Formlabs |

| Connectivity | Wi-Fi (2.4, 5 GHz) Ethernet (1000 Mbit) USB 2.0 |

| Software | Preform |

| Warranty | 12 months |

| Weight | 25 kg |

|---|---|

| Notify me when product will available |