No products in the cart.

3D printing technologies: comparison of SLA, DLP and MSLA Leave a comment

3D Printing Technologies: SLA, DLP, and MSLA Comparison

3D printing technology has come a long way since its inception, with new and improved methods emerging every year. Among the most popular 3D printing technologies are Stereolithography (SLA), Digital Light Processing (DLP), and Masked Stereolithography (MSLA). Each of these technologies has its unique advantages and disadvantages, and the choice of which one to use will depend on the specific application.

Stereolithography (SLA)

SLA is one of the earliest forms of 3D printing technology and is considered the gold standard for high-precision printing. SLA uses a laser beam to solidify resin layer by layer, building the final object. SLA is known for creating high-quality prints with a smooth surface finish, making it ideal for applications where precision and detail are crucial. However, SLA is slower than DLP and MSLA, and it is also more expensive due to the cost of the laser beam used in the printing process.

Digital Light Processing (DLP)

DLP is a faster 3D printing technology compared to SLA, as it solidifies the entire layer at once using a digital light projector. DLP is ideal for applications where speed is a priority and is also cheaper than SLA due to the lower cost of the digital light projector. However, DLP prints may not have the same level of detail and precision as SLA prints, and the surface finish may not be as smooth.

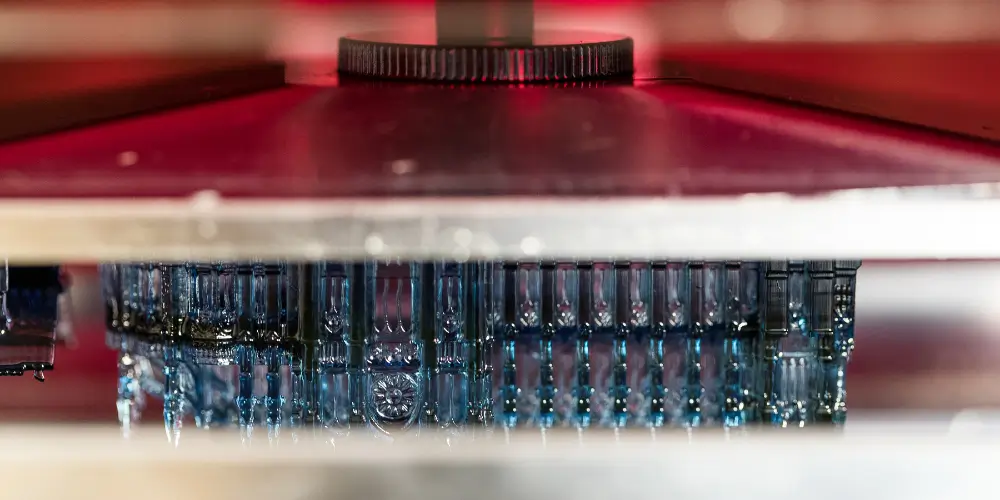

Masked Stereolithography (MSLA)

MSLA is a newer 3D printing technology that combines the basic principles of SLA and DLP. MSLA uses an LCD screen as a light source, and the light from the screen is directed onto the resin, solidifying it layer by layer. MSLA is faster than traditional SLA but slower than DLP and allows for high-resolution prints with a smooth surface finish. MSLA is considered a cost-effective alternative to traditional SLA or DLP technologies, making it an attractive option for hobbyists and small businesses. However, the quality of MSLA prints may not be as high as that of traditional SLA or DLP.

In summary, the choice of 3D printing technology will depend on the specific application, with each technology having its advantages and disadvantages. SLA is ideal for applications where accuracy and detail are crucial, DLP is ideal for applications where speed is a priority, and MSLA is ideal for cost-effective printing. Regardless of the technology used, 3D printing is sure to continue revolutionizing the manufacturing industry and bringing new and exciting possibilities to the world.